Product Fulfillment Strategies for the Holidays

As predicted, online holiday sales are expected to rise double-digits again this year, up 14 percent from 2013 according to a forecast from Deloitte. Similar to last year, 2014 has a shorter holiday shopping season, with only 26 days between Black Friday and Christmas. In 2013, when there were only 25 shopping days, many e-retailers failed to deliver packages on-time after overpromising on last minute orders that couldn’t be fulfilled.

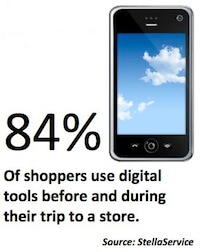

With another recording breaking online shopping season fast approaching, its clear brands need be prepared for the holiday rush with scalability and flexibility to meet demand. However, being prepared is no longer enough. With the number of online choices growing exponentially, brands must deliver a seamless online shopping experience that allows consumers to easily find items and convert.

Personalization & Cross Selling

Strengthening online consumer relationships can be a challenge. Shoppers have become less brand loyal and more concerned about finding the best value. To capitalize on this trend, brands should rely on customization and personalization to draw in consumers. Tracking order history and offering dynamic, custom landing pages can help drive consumers to the shopping cart. Also, remember to cross sell items with suggestions like “since you bought this you may also like this.” Creating a personal experience allows shoppers to feel a stronger connection with your brand. Don’t forget to include bounce back offers.

It’s all about the Experience

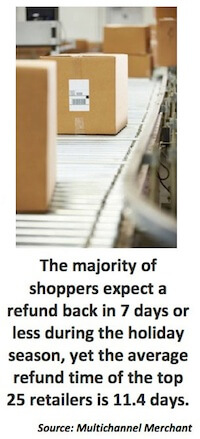

Consumer expectations for online shopping has never been higher. Brands are typically capable of delivering a positive experience on the front end, but after the “Place Order” button is hit many companies struggle to deliver on the promises they made prior to purchase. Delayed delivery times seem to be the greatest offender. During the holiday season, orders can be five to 15 times higher than the average week. Temporary workers are often needed to cover the additional workload. However, without proper planning and training your seasonal staff could be more of a burden than a help.

Know Your Inventory

Having a streamlined fulfilment process begins with knowing your inventory and product velocity. Top selling items should be placed in hot pick zones in the front of the warehouse to reduce walking distance and increase productivity. Keeping close tabs on your inventory can also help reduce backorders. Ensure your shopping cart inventory is in synch with your OMS/WMS.

Choose Your Carrier Wisely

Although the new DIM weight rates won’t kick in until after the holidays, brands should analyze their shipping practices to eliminate invoice surprises. With residential shipping outpacing commercial, brands should utilize all the tools at their disposal including zone optimization, air vs. ground prioritization and free shipping vs. transit time pressure. Be sure you have shared projections with your shipping carriers. Can you get extended pickup times for late day shipments? Brands should also alert carriers when additional trailers are needed due to increased parcel volume.

Ensure Operational Staff is up to Speed

Having solid systems and processes in place will ensure a smooth transition from off season to peak season. Consider prepacking items or staging items to streamline processes during the holiday rush. Many fulfillment centers hire seasonal workers to keep up with demand. Be sure to have a simple, but thorough training program in place to ensure speed and accuracy when fulfilling orders. Assess the strengths of your seasonal workers and place them in positions where you can capitalize on their skills. Assign workers to replenish items such as packing materials to maximize pick/pack productivity.

Set Realistic Order Placement Deadlines

Last year many brands extended their deadline to place orders for guaranteed delivery by Christmas Eve. The unanticipated surge in last-minute orders overwhelmed many carriers including UPS, who were unable to keep up with demand and missed the holiday delivery date. This year UPS is nearly doubling the amount of seasonal workers it is hiring – from 55,000 to 95,000. It will also be opening an additional 50 hub sorts in existing buildings to increase capacity and through-put. Be sure you review and understand your carriers’ holiday schedule for order pickup and delivery times.

Focus on Continuous Improvement

While many brands and carriers are taking the lessons learned from the 2013 holiday season and tweaking their processes to improve operations, this year is sure to present new and unexpected challenges. Knowing how to keep up with demand is critical, but brands also need to understand their consumers’ expectations when it comes to order fulfillment, returns and customer service. Remember, it is still not too late to make changes that will ensure a smooth and productive holiday season.

About PFC Fulfillment

At PFC, our clients’ success is our number one priority. Since 1974, PFC has delivered outstanding results, with turnkey solutions in fulfillment, e-commerce, and contact center – all backed by leading technology. Brands who partner with PFC have historically achieved considerable cost savings in excess of 35 percent and have significantly improved their turn times. PFC allows clients to focus on their big picture business goals, while skillfully managing all the details. For more information call (800) 493-7063.